Nanowatts Scientific Laboratory ISO ACCREDITED Services

Materials Testing and Characterization

Consumer Product Testing and Quality Assurance

Materials Testing and Characterization

Insights into the properties, and performance of your materials by

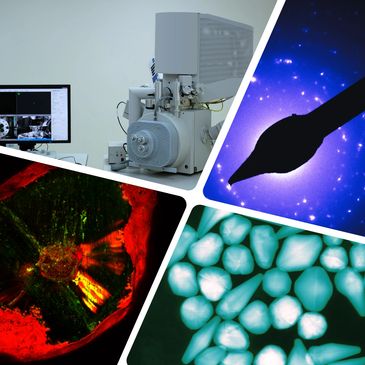

- Electron microscopy lab (SEM, TEM, FIB, AFM)

- Molecular and chemical analysis (FTIR, Raman, TGA)

- Chemical material analysis (XRD, XPS, XRF)

- Surface, morphology, and defect characterization

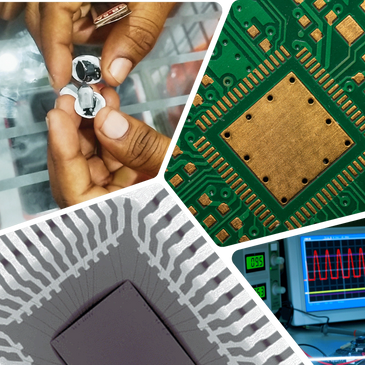

Nanofabrication and Microelectronics

Consumer Product Testing and Quality Assurance

Materials Testing and Characterization

From concept to prototype, we provide expertise to support your micro and nanotechnology projects.

- Nanofabrication facilities including lithography, etch, Deposition and packaging.

- Assistance with design, mask making & prototyping services.

- Development of process, device integration and packaging.

Consumer Product Testing and Quality Assurance

Consumer Product Testing and Quality Assurance

Consumer Product Testing and Quality Assurance

Helping you to improve, and validate your products with scientific precision to meet industry standards and expectations.

- Serving industries in electronics, automotive, medical devices, paint & raw materials.

- Failure analysis and root cause study services.

- Product quality assurance.

- Consumer product inspection.

Our Lab and Testing Facilities

Our Lab and Testing Facilities

Consumer Product Testing and Quality Assurance

Our innovative facilities boast modern equipment and technology specifically tailored for nanofabrication, product inspection, nanotechnology based material testing, ensuring precise and reliable results. We provide the ideal setting for comprehensive analysis and innovation in nanomaterial research.

Advanced Microscopy Services

Our Lab and Testing Facilities

Consumer Electronics Testing

Explore the complex world of materials at the nanoscale with our advanced microscopy services, offering unparalleled resolution and precision for detailed analysis. Our instruments and expert technicians let us uncover hidden structures and properties, providing invaluable insights on your research.

Consumer Electronics Testing

Our Lab and Testing Facilities

Consumer Electronics Testing

Elevate your electronics product reliability with our comprehensive testing services, meticulously designed to ensure products to meet industry standards and exceed our customer expectations. From durability assessments to performance evaluations, our expert team delivers actionable insights to optimize products.

Our versatile scientific testing solutions

We don’t just test, we solve problems.

- Material composition XRF analysis lab

- Reverse engineering and counterfeit tests

- Mechanical and deformation study lab

- IC and PCB quality inspection lab

- Polymer and rubber materials testing lab

- ISO ASTM root cause failure

- Environmental stress & durability testing

Material Testing Services

Material Study Lab

- Industrial materials characterization

- Chemical material analysis

- Solid state characterization

- Quality Control Analysis

- Mechanical deformation & fatigue

- ISO ASTM root cause failure

Material Science Tools

- Scanning Electron Microscopy (SEM)

- Transmission Electron Microscopy (TEM)

- X-ray product inspection

- Elemental composition analysis

- Electronic materials failures

Materials Insights & Inner Structure Analysis

- We dismantle and analyze products to understand their internal design, construction, and functionality. This helps uncover manufacturing methods and identify areas for improvement.

- Redesign and cost optimization of materials used and design choices for optimize manufacturing, reduce costs, and create smarter, more efficient next-generation products.

ISO/ASTM CASE STUDY REPORTS

01/11

Testing Made Remote

Our Global Testing Services

Ship your test samples, and our expert team in India handles the rest. We work with customers worldwide reach across Europe, Asia, USA and Oceania. We have sales office and logistics hubs to ensure seamless samples handling support globally.

We also assist with customs clearance, shipment paperwork, toxicology reports, and MSDS compliance to make global testing simple and stress free.

Small Products Development

Early Stage Innovation

We support startups and small companies in transforming ideas into working solutions through proof of concept (POC) development. From low-volume prototyping and MVP builds to pilot runs and design validation testing (DVT/EVT/PVT), we help bridge the gap between concept and mass production.

Research to Products

Our lab conducts environmental testing, electrical stress, mechanical stress and reliability studies, and toxicology safety evaluations to make sure your products are in compliance with industry and regulatory standards.

We also can help with small batches to improve a product, test it, and provide feedback before moving to large-scale production. We help small companies integrate their devices into suitable electronic packages, making them market-ready.

Visit our Product Testing Lab

COMPREHENSIVE lab testing expertise

Reverse Engineering

Unlock your electronic device secrets with our flexible reverse engineering services, meticulously dissecting and analyzing products to understand their inner workings. Our expert team uses the latest techniques to reverse engineer schematics, components, and functionalities, offering valuable insights into innovation and product enhancement.

- Product purchase and product teardowns.

- Product 2D, 3D CT X-ray inspections.

- Material composition analysis and more.

Product Validation

Ensure your products reliability and market readiness with our meticulous product validation services, meticulously designed to confirm performance, safety, and compliance with industry standards. Our expert team utilizes advanced testing techniques to provide extensive validation reports, enabling you to confidently launch your products into the market.

- Product cross section inspections.

- Root cause case studies.

- In depth product analytical analysis

Quality Assessment

Gain assurance in your materials quality with our elevated quality assurance assessment services, where we evaluate and confirm your products' integrity, consistency, and reliability. Our expert team dives into advanced testing protocols and industry-leading techniques to deliver kick off assessments, ensuring your materials meet the highest quality and performance standards.

- ASTM/ISO standard tests.

- Environmental ecotoxicity assessment.

- Electromagnetic compatibility test and solutions.

Pro Visual Inspection

At Nanowatts, outsourcing services for semiconductor testing for IC's, electronic products, failure analysis, material testing & analysis, X-ray Inspection of PCB's, Bio tech services where profound attention to detail ensures the detection of even the slightest defects in your materials or products. Our expert inspectors employ advanced techniques and equipment to provide thorough assessments, providing you with confidence in the integrity and reliability of your products and materials.

- Zoom in stereo microscope services.

- Optical micro inspection solutions.

- Advanced 2D, 3D, CD/CT X-Ray inspection services.

From your desk to our lab

Tailored Testing Solutions

- Fully remote on demand lab services.

- Ship your samples from anywhere, and receive certified reports all done online.

- Customized approaches designed to fit your unique products and challenges.

- From research to prototyping MVP. We work with startups and small companies.

Standards and Certifications

- Testing aligned with ISO global standards to support compliance and approvals.

- Data driven insights, with pictures during testing and full report delivered by our scientists and engineers using advanced instruments and methodologies.

Visit our Electronics Testing Lab

Electronics Reliability Faciilty

Semiconductor Testing

- IC Device reliability & failure analysis

- Electronic product teardowns

- IC and PCB Cross section inspection

- Reverse engineering and Counterfeit test

- Thermal and environmental cycle stress lab

- ISO ASTM root cause failure

Electronics Manufacturing Assurance

- Non destructive testing (NDT) lab

- PCBA Quality control assurance

- IC Decapsulation inspection

- PCB Assembly X-Ray inspection

- Consumer field reliability failures

Semiconductor Product Teardown Services

Semiconductor Die Level Analysis

- Module and multi chip packages decapsulation of SoP, PoP, BGA's, QNF & QFP die level analysis.

- Failure mode investigation of failed devices due to electrical overstress (EOS, ESD), die level contamination.

Visit our IC Failure Analysis Lab

Innovative material testing lab services

Semiconductor Testing and ATE Test Engineering

Chemical and Thermal Physio Analysis services

Chemical and Thermal Physio Analysis services

Our semiconductor testing facility houses next generation tools for silicon debug to the final die validation for wafer level testing to final packaged test chips.

- Board level, chip level, package level failure analysis.

- IC Decapsulation and IC delayering services.

- PCB reliability testing for growing electronic manufacturing sectors.

Chemical and Thermal Physio Analysis services

Chemical and Thermal Physio Analysis services

Chemical and Thermal Physio Analysis services

Elevate your understanding of materials with our comprehensive chemical and thermal analysis services, specifically designed to uncover critical insights.

- Environmental impact studies.

- Product toxicity investigations.

- Composite material analysis.

- Thermal degradation studies.

- Life cycle verification analysis.

- Surface roughness testing.

- Temperature dependent testing.

Polymer Testing and Product Chemistry

Chemical and Thermal Physio Analysis services

Industrial Raw Materials and Root Cause Analysis

We provide elaborate aid in conducting testing and analytical testing solutions to understand the performance, durability, and composition of polymers.

- Mechanical testing such as tear, shear and tensile strengths.

- Wear and Hardness testing.

- Polymer Identification lab.

- Aging, weathering, and durability studies for product reliability.

Industrial Raw Materials and Root Cause Analysis

Industrial Raw Materials and Root Cause Analysis

Industrial Raw Materials and Root Cause Analysis

Our expertise involves in identifying defects, verifying specifications, and conducting detailed root cause investigations for failures.

- Dry film thickness inspection.

- Advanced impurity tests.

- Fracture ISO failure analysis modes and its origin investigation.

- Surface defects root cause ISO case study services.

- Reverse engineering lab services for industrial raw materials.

Metal Alloys and Composite Analysis

Industrial Raw Materials and Root Cause Analysis

Mechanical Deformation studies and Testing

Surface areaarostructure to metallurgical properties, we help you understand and optimize your materials for critical applications and performance.

- Metallography and microstructure analysis.

- Particle size analysis.

- Elevated temperature tests.

- Composite characterization of fiber matrix interface, fracture toughness, and failure modes.

- Surface area analysis using BET analyzer.

Mechanical Deformation studies and Testing

Industrial Raw Materials and Root Cause Analysis

Mechanical Deformation studies and Testing

Dive deep into the behavior of materials under mechanical stress with our specialized mechanical deformation studies and unique testing services.

- Load displacement studies.

- Young's modulus investigation.

- Fatigue, wear, friction testing.

- Hardness and abrasion tests.

- Non Destructive Testing (NDT)

- Metals reverse engineering lab.

- Custom Mechanical Experiments for specialized applications.

- Impact tests.

Leading Nano Biotechnology Testing Solutions

In Vitro Testing

Bio Visual Imaging Services

Bio Visual Imaging Services

At our Nano Biotechnology Lab, we provide integrated in-depth In vitro Testing services, providing sophisticated analysis of biological interactions at the nanoscale level. Our expert team leverages from advanced techniques and equipment to simulate biological environments, easing research and development in fields such as drug delivery, biomaterials, and nanomedicine.

- In Vitro dental testing solution.

- In Vitro Microstructure analysis services.

- In Vitro analytical micro assay solutions.

Bio Visual Imaging Services

Bio Visual Imaging Services

Bio Visual Imaging Services

At our microscope facility we specialize in biomaterials imaging, offering high-resolution imaging solutions to visualize and analyze biomaterials at the microscopic level by employing high end microscopy techniques and advanced imaging software, our expert team offers detailed insights into the structure, composition, and interactions of biomaterials.

- Bioluminescence and Biofluorescence support.

- Advanced cryo imaging services.

- Biological sample preparation.

Medical Products Testing

Bio Medical Device Prototyping

Bio Medical Device Prototyping

At our medical device testing laboratory, we specialize in leading edge medical products testing, ensuring the safety, efficacy, and compliance of your devices. With our avant-garde facilities and experienced professionals, we dive into rigorous testing protocols to provide precise assessments and support your product development journey.

- Biomedical polymer chemistry and assessment.

- Metal leaching and Ion release studies.

- Bio-metal metallography investigation.

Bio Medical Device Prototyping

Bio Medical Device Prototyping

Bio Medical Device Prototyping

At our microfluidics research group, we specialize in medical devices and laboratory-on-chip prototyping, providing precision engineered solutions for healthcare innovation. Our expert team harnesses advanced microfluidic technologies to accelerate the development of medical devices and lab-on-chip platforms, empowering researchers and clinicians to address complex healthcare challenges.

- Nano & micro fabrication services and support.

- Microfluidics stamps and device prototyping.

- PDMS,PMMA Glass bonding.

Experts Insights & Articles

PCB Soldering Reflow Issues with BGAs & SMTs: Production Problems.

Optimizing PCBA 's BGA Reflow Soldering: Common Defects, Causes, Detection Methods, Root cause, Production and Failure inspection techniques. Problems with PCB solder reflow on BGA's and SMT's comes from poor solder joints, voids, flux quality, reflow temperature and needs PCB inspection and cross section analysis.

An In Vitro Study of Dentin Materials and Sharper Insights

Today, modern dentistry relies heavily on advanced dental materials to provide patients with durable, esthetically pleasing, and biocompatible dental restorations. Our lab explores the rigorous testing and methods involved in In Vitro dental studies.

The Role of a Material Testing in Quality Control and Quality Assurance

In the world of industrial material analysis and manufacturing, construction, and product development, ensuring the quality and reliability of materials is challenging. In this article we explore the crucial role of a material testing labs and why their work to make better materials for modern industry products.

Electrical Over-Stress (EOS) or ESD failure analysis on Integrated Circuits (IC's)

Electrical Over Stress (EOS) is a major issue in the design and manufacture of ICs, with significant implications for both OEMs and consumer electronics. By recognizing the differences between EOS and ESD. Recognizing the signs of EOS, and implementing robust safeguards to ensure the reliability and longevity of electronic products.

- Nano Fabrication

- Material Characterization

- Semiconductor IC Testing

- Materials Testing Lab

- Electronics Testing Lab

- Nano Bio Tech

- Electron Microscopy Lab

- X Ray Inspection Facility

- Polymer Rubber Test Lab

- Mechanical Testing Lab

- Consumer Testing Lab

- PCB Quality Assurance

- Contact Us

- IC Failure Analysis Lab

- Our Mission

- Spectrophotometer Lab

- XRF Testing Lab

- Blog

Nanowatts Technologies

80 ft Road, RMV 2 nd Stage, Bangalore 560094

Customer Support Help Landline : 91 8217618041

Copyright NanoWatts Technologies, Bangalore, India